What Is Liqud Filling Machine?

Automatic filling machine for liquid is a mechanical equipment for filling various liquids. It is widely used in various industries such as daily chemical and grease, filling different high-viscosity fluids. The liquid filling and capping machine has a compact and reasonable design, a simple and beautiful appearance, and easy adjustment of the filling volume.

According to different types of liquid filling machines, let's take a look at their working principles!

What Are the Types of Liquid Fillier Machines?

By Filling Pressure Level of Filling Machine

According to the different levels of filling pressure, filling machines and equipment can be divided into atmospheric liquid filling machine, vacuum filling machine and pressure filling machine.

Atmospheric Liquid Filling Machine

The atmospheric pressure liquid filling machine for sale uses gravity filling, the liquid material box and the metering device are at a high position, and the packaging container is placed below. Under atmospheric pressure, the liquid automatically flows into the packaging container by its own weight, and the entire filling system is in an open state Work down. The filling speed only depends on the cross-sectional area of the liquid inlet pipe and the liquid level of the filling cylinder. Common filling liquids include wine and milk.

Vacuum Bottle Filler

The vacuum filling machine uses the vacuum system configured in the filling machine to keep the packaging container at a certain degree of vacuum, so that the liquid in the liquid storage tank is injected into the packaging container under a certain pressure difference or vacuum state. Since the filling process is accompanied by a vacuuming process, its structural principle is different from that of a normal pressure or equal pressure filling machine, and has its own unique side. Generally used for liquids with high viscosity, such as oils, syrups, fruit wines, etc. are more common.

Pressure Filling Machine

The pressure filling machine is also called high pressure filling machine. By changing the pressure in the liquid storage tank, the period is higher than the pressure in the bottle, and the liquid flows into the bottle by the pressure difference. High-speed production lines mostly use this filling method, which is suitable for filling gas-containing liquids, such as beer, soda, champagne, etc.

By Automation Degree of Filling Machine

According to the degree of automation of filling operation, it can be divided into semi-automatic liquid filling machine and fully-automatic liquid bottle filling machine.

Semi Automatic Liquid Fill Machine

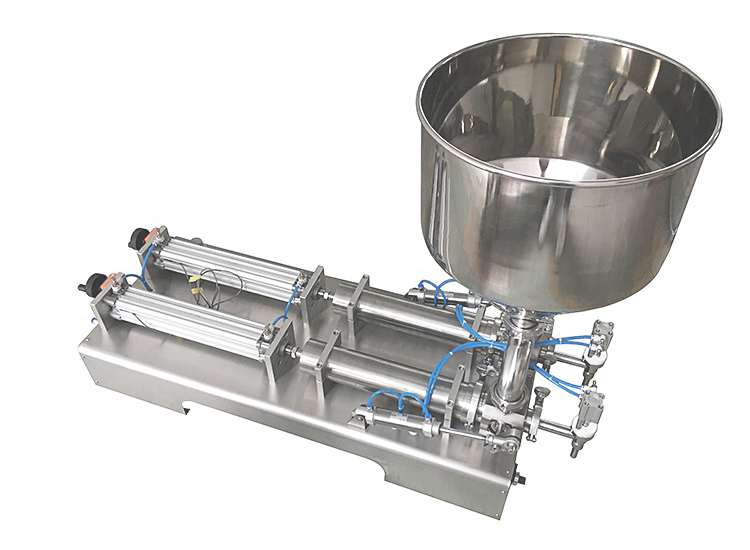

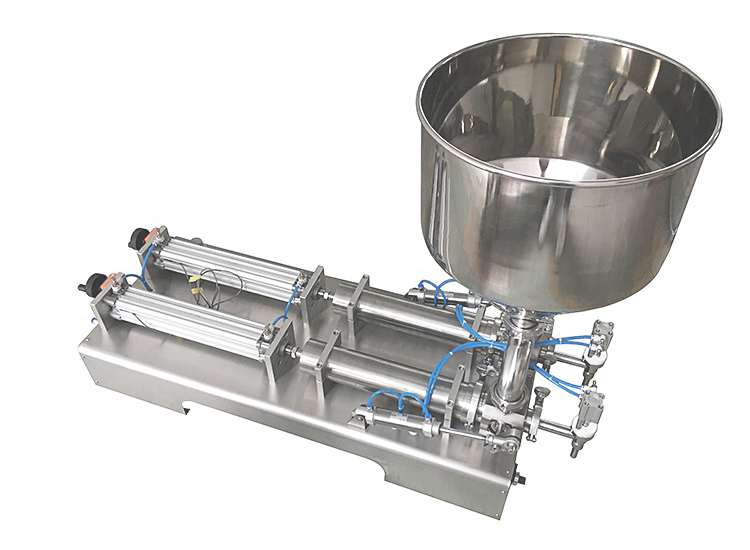

Semi automatic bottle filler is one kind of hand operated filling machine for liquid, which also can be divided into direct flow liquid filling and piston paste filling. The working principle of DC liquid filling is relatively simple. The filling method of constant current timing can accurately control the filling volume by adjusting the filling time under the condition of certain liquid level and pressure.

When the semi-automatic piston filling machine fills high concentration liquid, it extracts and pumps high concentration materials through the three-way principle that the cylinder drives a piston and rotary valve, and uses the magnetic spring switch to control the stroke of the cylinder to adjust the filling volume.

Fully Automatic Container Filling Machine

Automatic filling machines are generally divided into DC liquid filling machines and piston liquid filling machines. Their working principles are the similar, but they differ with different degrees of automation.

When the bottle enters the transmission belt, it will pass through the infrared sensor. During this period, the bottle handling machine will continue to sort out. The bottle that has previously entered and transmitted to the bottle passing through the infrared sensor will be gradually released to the conveyor belt after filling. This can realize no bottle and no work and avoid resource waste. When the filling reaches the specified weight, the filling will be stopped.

In addition, the automatic liquid canning machine is widely used, filling liquid, nursing liquid, oral liquid, skin care liquid, disinfectant, eye washing liquid, nutrient solution, injection, pesticide, medicine, perfume, edible oil, lubricating oil and other industries liquid.

As the professional liquid filling machine manufacturer in China, liquid bottle filler designed by SED Counter is suitable for bottle filling and sealing, using syringe pump filling, centrifugal capping or customized ampoules melting and sealing, no bottle no filling. The whole machine adopts food grade stainless steel, which conforms to GMP standard. Fully automatic and intelligent operation, easy to maintain and clean. According to your needs, we can provide filling machines with different heads. Welcome to leave your message!

Wechat

Wechat