We always get questions from our clients about foil sealing. Which way is suitable for their packages?

As we know, both induction sealing and heat sealing is to be used in the packaging industry. The biggest difference lies in the way and principle of sealing. There’s no need to touch the package itself when doing induction sealing. While heat sealing requires contact with the package to finish the sealing process. The principle behind the application of both seals will also be explained in this article.

What Is Induction Sealing?

Inductive sealing uses the principle of electromagnetic induction to seal product packaging without contact.

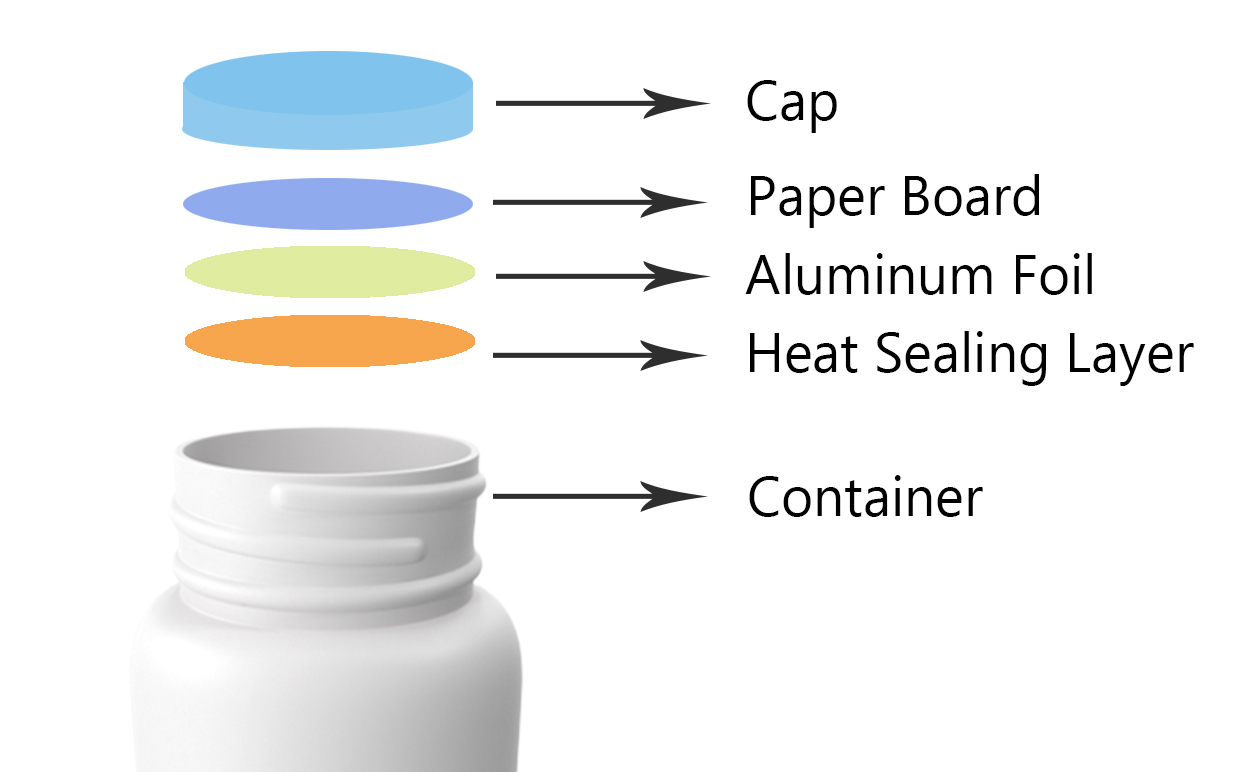

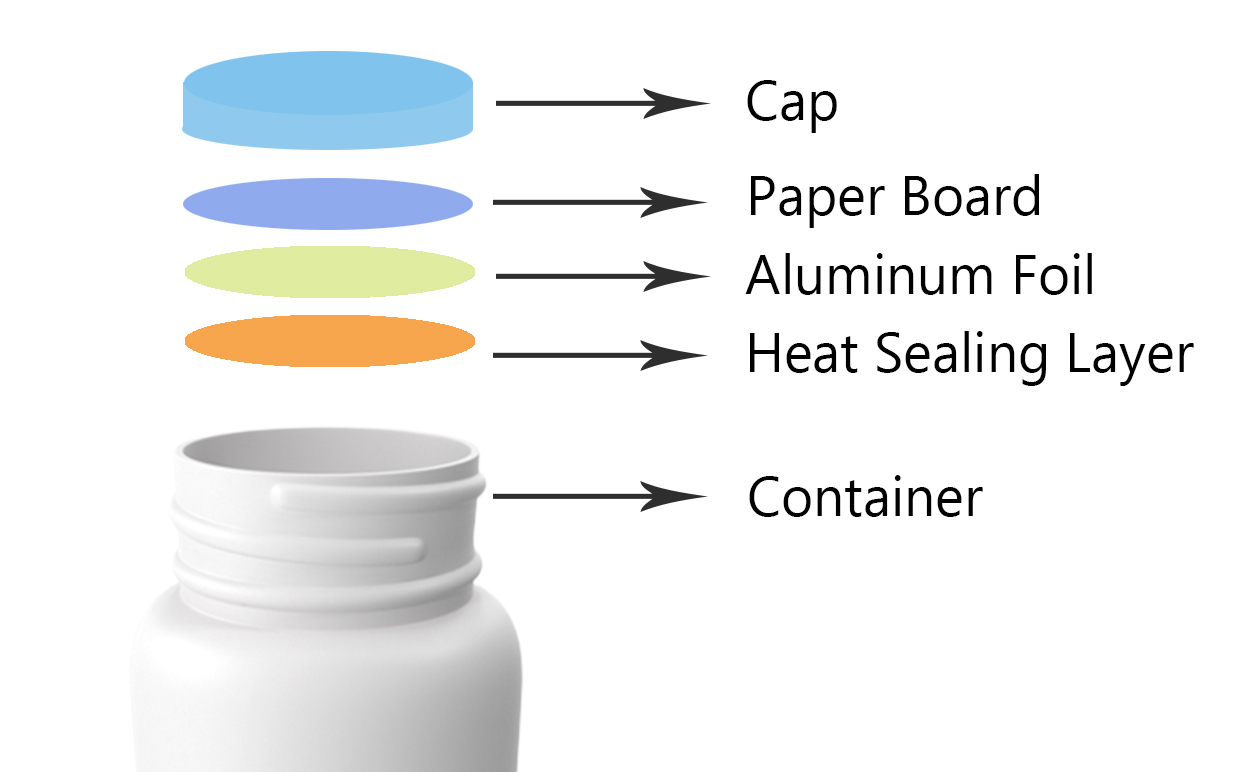

Usually, after the induction sealing machine is powered on, it will generate a high-speed alternating electromagnetic field, which will form an induction eddy current on the aluminum foil. It causes friction between the molecules of the aluminum foil to generate an instant temperature rise, and fuse the hot melt adhesive coated on the surface of the aluminum foil to the bottle mouth.

At the same time, the weak adhesive layer between the aluminum foil and the cardboard drops rapidly, penetrates into the fiber of the cardboard, and separates the aluminum foil from the cardboard.

The induction sealing method is suitable for aluminum foil sealing of plastic bottles, glass bottles, ceramics and other non-metallic containers. Through electromagnetic induction heating (non-contact), the aluminum foil is sealed on the bottle mouth to achieve a sealing effect.

Benefits of Induction Foil Sealing

Fast Sealing Speed: No need to warm up, start to use directly.

Good Sealing Performance: With moisture-proof, anti-oxidation function.

High Security: Anti-theft, anti-counterfeiting.

Wide Range of Applications: Suitable for sealing bottles of various materials and sizes, including plastic bottles, glass bottles, etc., without touching the packaging materials.

What Is Heat Sealing?

Heat pressure sealing is to heat the material at the sealing point to make it reach a viscous flow state and then apply pressure to make it sticky. Generally, there are professional heat-sealing sealing machines to complete the work.

Heat sealing needs to take into account the heat sealing performance of the packaging material, including the heat sealing performance of the material before cooling to the ambient temperature after heat sealing, and the heat sealing strength after cooling and stabilization.

It is necessary to control the heat-sealing temperature when using a heat-sealing machine, to avoid the influence of the temperature being too high or too low on the sealing quality.

Benefits of Heat Sealing

Strong Durability: heat seal can withstand temperature and humidity changes in different ranges

Temperature Resistance: through heat-sealed and bonded packaging, the product can be well preserved at low temperature

Flexible Design: Existing technology includes both sealing of non-vacuum packaging and heat sealing equipment for vacuum sealing of packaging

Anti-theft: Its strong adhesive force provides higher anti-theft and anti-tamper performance

How Does An Induction Sealer Work?

The aluminum foil sealer machine is generally composed of a frame, a deceleration and speed regulation transmission mechanism, a sealing and printing mechanism, a conveying device and an electrical and electronic control system and other components.

After turning on the power and starting the foil sealer machine, the bottle to be sealed can be covered with induction sealing wads without preheating, and the bottle can be placed on the conveyor belt.

The bottle moves and passes under the sealer, where it is sealed. But it should be noted that the induction foil sealing machine cannot be used for aluminum foil sealing of metal containers, it is only suitable for cap sealing of glass or plastic bottles.

Bottle Materials Can Be Applied by Induction Foil Sealing

A wide variety of containers are suitable for induction foil sealing. Typically, HDPE, LDPE, PS, PET and PVC plastic bottles and glass containers can be sealed with foils.

Can Aluminium Foil Be Heat Sealed?

The answer is yes. In general, aluminum foil can withstand a high temperature of 270 degrees Celsius, so it is also a material that can be used in the heat-sealing packaging industry.

Aluminum foil packaging bags have many advantages as well, such as good barrier properties, shading, high and low temperature resistance, non-toxic and tasteless, and excellent softness.

Usually, the aluminum foil packaging we use in the food, pharmaceutical, chemical and other industries refers to the aluminum-plastic composite vacuum packaging, which has good moisture-proof and water-oxygen barrier functions.

Other Materials Can Be Heat Sealed

Plastics: polyethylene, polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC), etc.

Aluminum Foil

Board Materials

SED Counter has own the induction sealing technology for years, and the induction sealers we sold were widely praised by customers after the raise. This type of induction foil sealer is able to work continuously 24 hours. They can be connected with other equipment to set up a bottle packaging production line, or be used independently. Any questions or inquiries of the automatic induction aluminum foil sealing machine can be solved by SED Counter. Please feel free to leave your messages!

Wechat

Wechat