Description of Automatic Capsule and Tablet Counting Production Line

The automatic counting and filling production line is a complete solid particle product packaging line. Its packaging objects include hard capsules, soft capsules, tablets, augers, snack foods, hardware, etc., with a wide range of applications.

The whole line consists of bottle unscrambler, electronic counting machine, aluminum foil sealing machine, capping machine and labeling machine. After all machines are connected, they can run synchronously and ensure their stability. Each machine in the production line can be adjusted quickly and used independently, and the entire production line can be assembled and separated simply and quickly. The outer frame of the machine is made of 304 stainless steel, and the contact part is made of 316 stainless steel, which meets GMP requirements.

Applications of SED Automatic Capsule and Tablet Counting Production Line

Generally, many products are counted by grain, for example,customers eat chewing gum in pieces,so marking the number of products on the bottle can increase the customer experience. The exact number of products is particularly important. Our company provides such a counting and packaging solution.

A production line can automatically complete the processes of bottle washing, unscrambled bottles, feeding, counting and filling, plugging desiccant, capping, labeling, sleeve labeling, heat shrinking, boxing, etc.

Features of Automatic Capsule and Tablet Counting Production Line

Strong compatibility: fully compatible with solid preparations or solid particles

High degree of intelligence: multilingual control panel, self-check alarm functions

High efficiency: easy to operate, adjust, clean, maintain, low operating and maintenance cost

Small footprint: use area <30 square meters, low energy consumption

Simple operation: the man-machine interface control panel and PLC control system are adopted

Anti-high dust: make the machine run stably in high dust environment

Each machine can complete its work independently and has an independent operating system

Multi-machine linkage, fast separation and adjustment, ensure coordination of production processes

Bottle Unscrambler

Capsule Tablet Counting Machine

Desiccant Inserter Machine

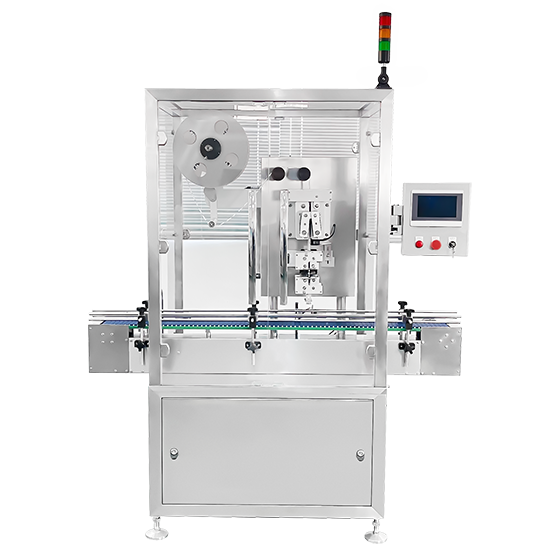

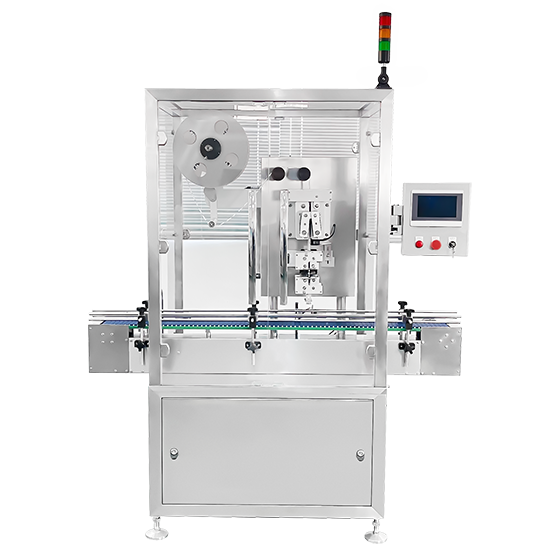

Capping Machine

Aluminum Foil Sealing Machine

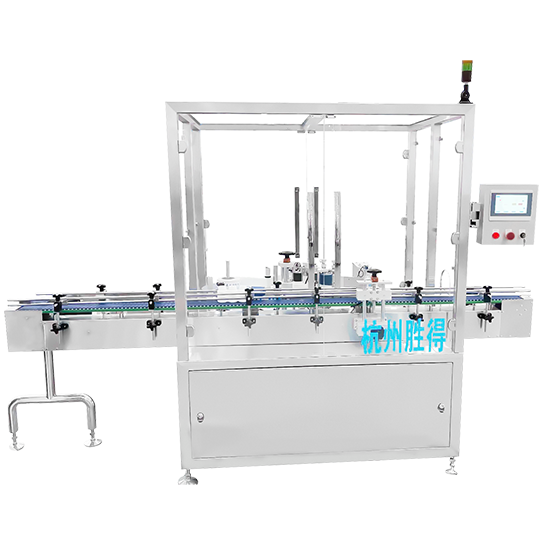

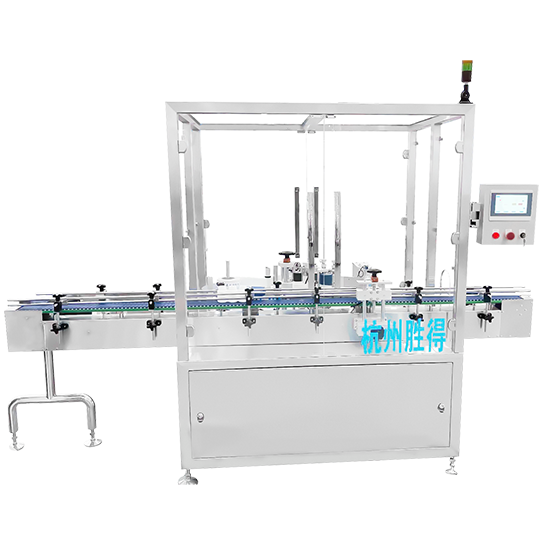

Labeling Machine

Wechat

Wechat